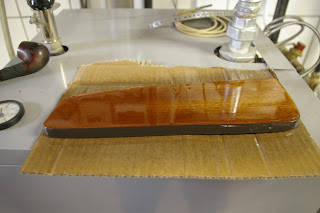

The dashboard we did after some period pictures. We used as many period correct parts as we could. The door was cut from an original Jaguar dashboard. 11 layers of clearcoats went on it.

The lock and the hinges are also period correct parts. jut like the chrome stop.

The Innocenti window system gave us a bit of trouble...

Thanksfully the trimmer was lazy to cut the winder's hole on the leather. His misstake was our gain :-D.

Period original steering wheel, retrimed in Connolly leather.

NOS Britax inetria seat belts make the final touches on the interiour.